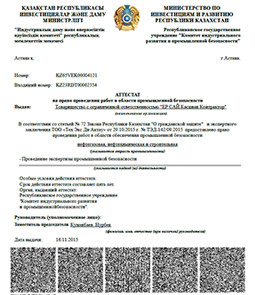

DTL was Established in 2013 and Accredited 2014 in accordance with International Standard ISO/IEC 17025 by “NCA” LLC (National Centre of Accreditation). The National Center of Accreditation is a full member of ILAC (International Laboratory Accreditation Cooperation) and a signatory to the ILAC MRA Mutual Recognition Agreement for the accreditation of testing and calibration laboratories (ISO / IEC 17025).

DTL is recognized and certified by “RMRS” (Russian Maritime Register of Shipping).